YOUR POSITION: HOME > Split Sets > Split Set Stabilisers

Price:according to your drawings

Material::Q235B, Q355B

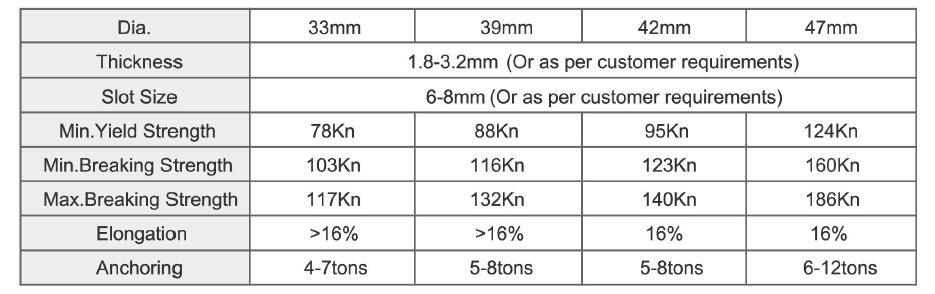

Size:33mm, 39mm, 42mm, 47mm

DESCRIPTION:The split bolt is a new type of anchor that fully anchors the rock and actively strengthens the surrounding rock, its three-dimensional part is a longitudinally slit high-strength steel pipe.

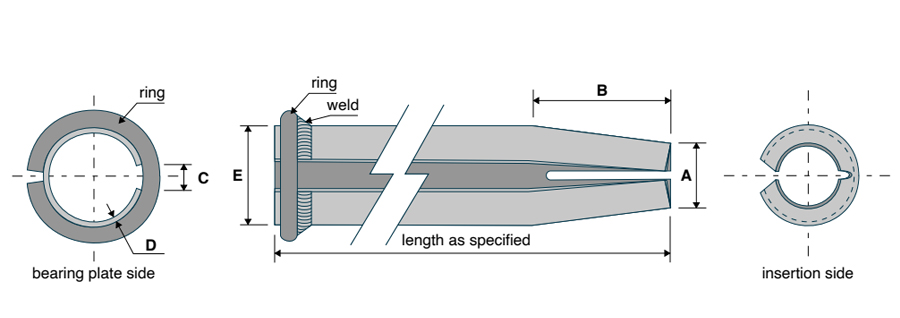

Split Set Stabiliser

Specification:

SS-33(mm)

SS-39(mm)

SS-42(mm)

SS-47(mm)

A

Taper Diameter

28

30

34

40

B

Taper Length

60

65

75

70.5

C

Slot Width

12

16

20

25.5

D

Steel Thickness

2.3

2.3

3

3.2

E

Bolt Size

33

39

42

47

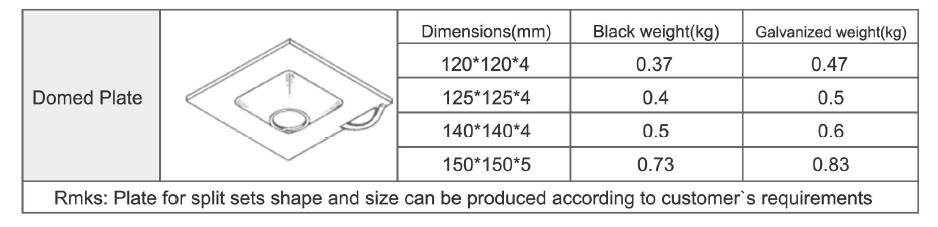

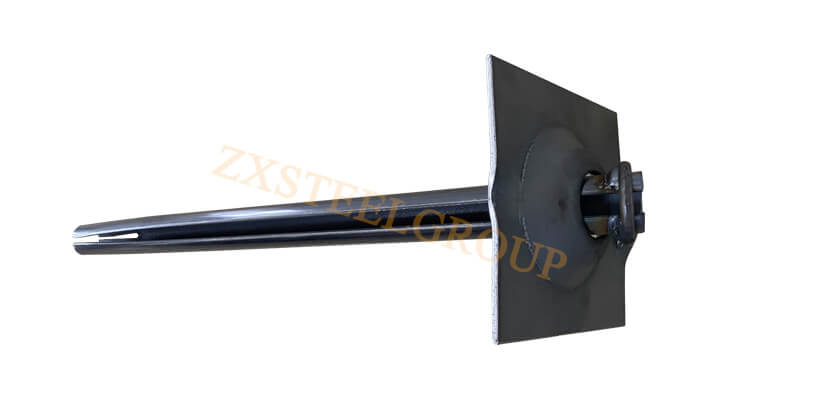

Domed Bearing Plate

Split set domed bearing plates uniquely combine high strength with light weight, and are integral parts of the split system.

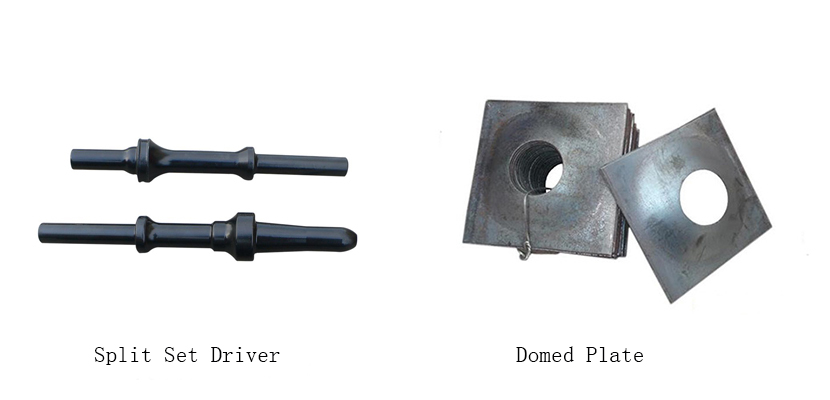

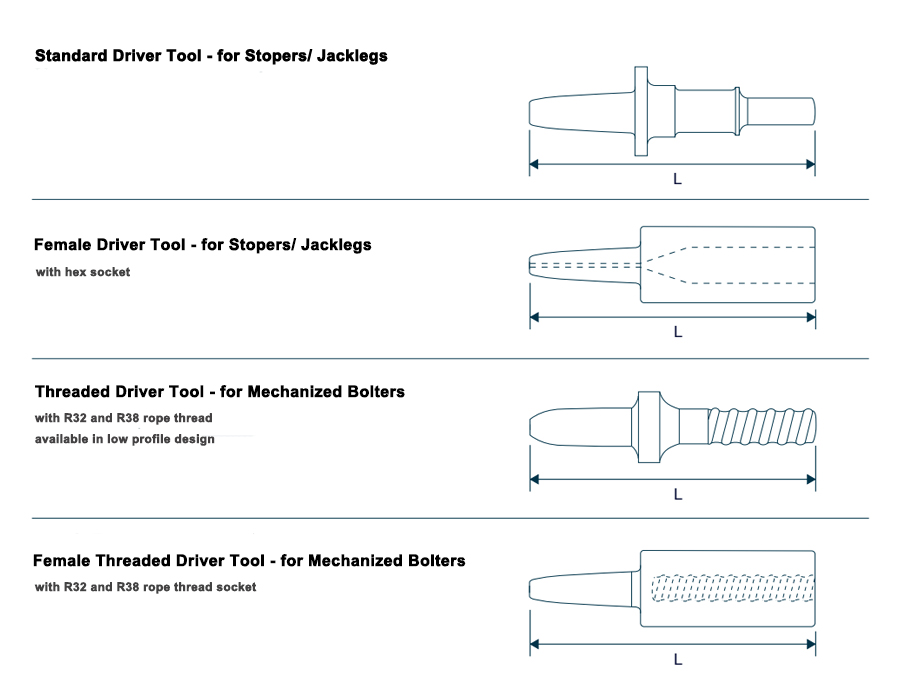

Driver

A simple driver tool adapts the drill for easy insertion. One end fits the tube; the other fits the drill chuck or drill steel.

Friction bolt driver tools are made of high-strength heat-treated alloy steel, designed for long life.

Utility Hangers

Working principle

Install the split set in a bore that is smaller than the pipe diameter, at the same time, three forces will be applied to the surrounding rock, one is the radial pressure on the hole wall over the entire length of the split set, one is friction to stop the surrounding rock from falling, there is also a bearing force for the split bolt pallet, these three forces make the surrounding rock more stable.

How it works

The Split Set stabiliser system has only two parts-a tube and a bearing plate. The high-strength steel tube has a slot along its length; one end is tapered for easy insertion, and the other has a welded ring flange to holdthe plate. That's all.

With the bearing plate in place, the tube is driven into a slightly smaller hole, using the same standard percussion drill which made the hole. As the tube slides into place, its full-length slot narrows; the tube exerts radial pressure against the rock over its full contact length. Plate loading is generated immediately. The result is a tight grip which actually grows stronger with time and ground movement.

Technical characteristics1,High-strength alloy strip steel;

2,The easiest to install;

3,No anchoring agent required;

4,The friction between the anchor and the rock mass is large;

5,High shear and tensile strength;

6,Equipped with a high-strength tray, the tray is evenly stressed;

7,The roadway height is greater than the bolt length.

Applications:

In underground mines

Every kind of underground mine uses Split Set friction rock stabilisers for ground support. Miners also use them to pin mesh, hang conveyors, hold pipes and cables, secure rails in place, and for other needs.

In tunnels and other excavations

Split Set stabilisers have solved many problems for contractors in constructing and maintaining railway and road tunnels, hydro power tunnels, powerhouse and storage caverns, shafts, water and sewage tunnels, and others.

And above ground

Open-pit mine and quarry operators use them to stabilise highwalls. Contractors find Split Set stabilisers ideal for attaching screen to control spalling on cuts

Get the Price

Online Chat

To top