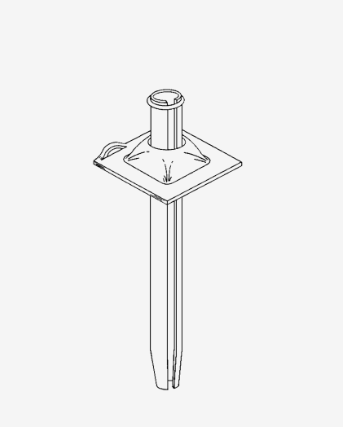

The split set is a slottedsteel tube with one end tapered for easy insertion into a drill hole. The other end has a welded ring flange to hold the bearing plate.

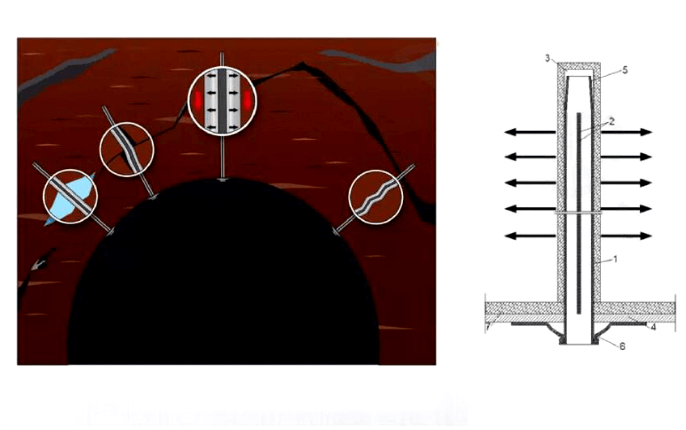

The stabilizer is insertedi into a hole slightly smaller in diameter than the tube, using a simple driver too fitted to the drill. As the tube enters, its diameter is compressed and the slot partially closes. This exerts radial forces along the length of contact with the rock, providing the friction which holds the rock together. The driving force of the drill actively loads the bearing plate against the rock.

Outside Diameters/mm:Φ30,Φ33,Φ40,Φ43(±0.5)

Length:1200、1500、1800、2000、2500

Material:Q235,16Mn,20 Mnsi

the worlk of Split Set Stabilisers

the worlk of Split Set Stabilisers

1. Drill the hole.

2. Replace the drill steel with a driver tool.

3. Slide the plate on the tube.

4. Drive the tube in with the drill / drifter.

5. Rock Bolt Pull Tests Prove Sustained Grip.

6. Pull tests help verify the effectiveness of the stabilizers upon installation and over periods of time. Pull collars may be used on selected tubes for later testing.

1. The surface of Split Set shall be flat and free from serious strain and corrosion. The weld shall be free of cracks, air holes and slag inclusions, and it is not allowed to burn through the pipe wall. The plate shall be able to move freely on the rod body. It is suitable for 170o-190o that the joint of retaining ring and the opening of pipe joint are staggered with each other.

2. Pull off force of retaining ring weld ≥ 80KN, ultimate tensile strength of rod ≥ 110kN, initial anchorage force ≥ 25kn / m, and tray bearing capacity ≥ 65kn.

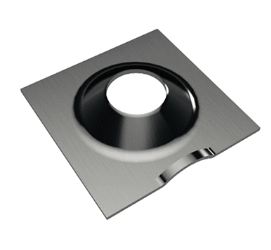

Split Set Driver Tool

Split Set Driver Tool

Place the adapter on the stern of the rock driller, then place the split set on its respective plate, align with the driller in advance, and then dock with the driller until the plate contacts the rock.

Initial anchoring force

Pull off load of pipe ring

Tensile breaking capacity of anchor tube

The corrosion resistance of A3 steel is higher than that of A3 steel,which is good for long-term use

Fast and easy installation by percussion

Fast and easy installation by percussion

Immediate full length support

Immediate full length support

High plate loading generated immediately

High plate loading generated immediately

Tight grip and strong capacity to shearing

Tight grip and strong capacity to shearing

Split Set grip increases with rock shifts

Split Set grip increases with rock shifts

Split Set can be installed manually or fully mechanized

Split Set can be installed manually or fully mechanized

Split Set allows drainage

Split Set allows drainage

No resin, no mixing, no shelf limit, no torquing

No resin, no mixing, no shelf limit, no torquing

Henan Zongxiang Heavy Industry Import & Export Co., Ltd, established by experienced crew on the rail & track field, is a professional & reliable supplier that provides all kinds of rail & track accessories.

As an international trade subsidiary of Zhongxiang Steel Group Inc., was founded in 1997. We have more than two decades experience on this field, covering an area of 33,000 square meters, with about 300 employees, 4 production lines, 2 R & D department, and 5 quality control staff. With advanced technology, powerful processing capacity and excellent service, our products have been well recognized by our customers from domestic & overseas market.

Our products mainly used by railroads, mining companies, heavy industries, overhead crane, railroad and tunneling industry, transit authorities, and operators of port facilities.We have the inventory, resources, and experience to meet your needs.

Online Chat

To top