As an effective means of anchoring, self drilling anchor bolt can be widely used in advanced support, radial support, slope reinforcement, roadbed reinforcement and tunnel disease control.

Self-advancing bolt is mainly used in the excavation and support construction of fault fractured zone, overcoming the problems of ordinary mortar bolt such as hole collapse, rod insertion failure, inadequate grouting, etc., giving full play to the role of bolt support, improving the bearing capacity of surrounding rock, ensuring the overall stability of surrounding rock, and having good application value.

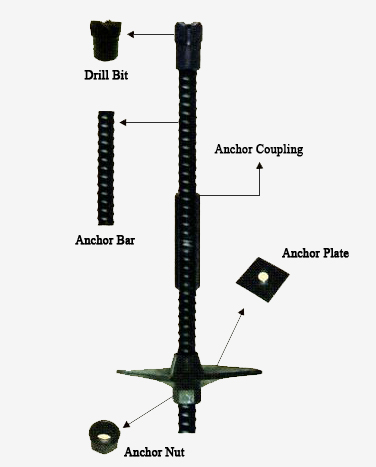

Drill Bit: with strong penetrating power, the anchor bolt can pass through various rocks.

Anchor Bar: full-length wavy continuous thread, which is convenient for installing drill bit, anchor coupling and archor nut, and can be cut and connected at will.

Anchor Coupling: the anchor bolt can be lengthened to the designed depth while drilling.

Anchor Plate: can bear greater stress of surrounding rock.

Anchor Nut: It can transfer the stress of surrounding rock to the backing plate.

The Application of Self Drilling Anchor Bolt

The Application of Self Drilling Anchor Bolt

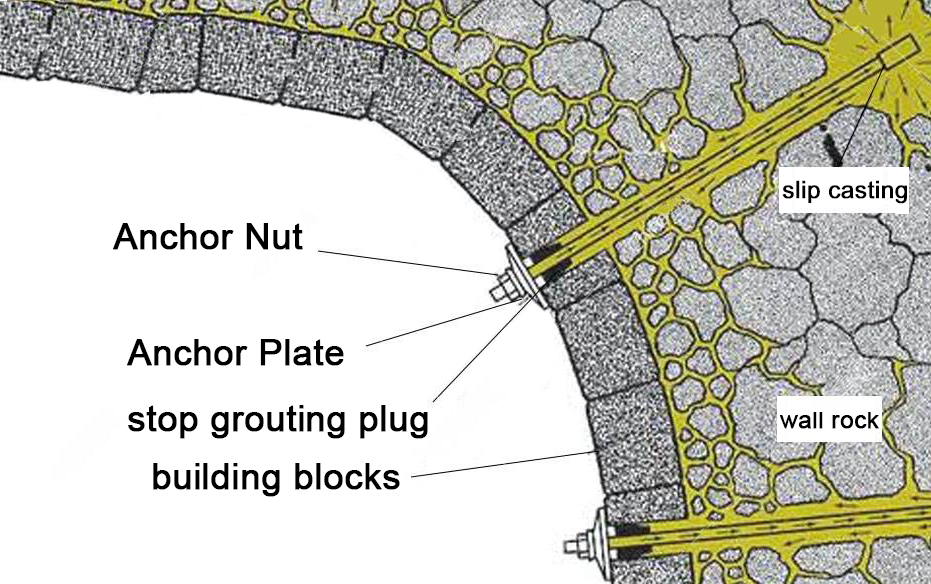

1. The self-advancing anchor rod shall be drilled according to the designed depth, and cooling water shall be added when drilling.

2. Unload the drilling rig, insert the grout stop plug into the rod body, and insert it into the hole to prepare for grouting.

3. Connect the quick grouting joint with the tail end of the anchor rod, and connect the other end of the grouting joint with the grouting machine.

4. Start the grouting machine for grouting, and shut down when the grouting is full and the pressure reaches the design value.

5. Install the backing plate and nut, and tighten the nut, and the installation is finished.

R-type has a rope thread, and is available in sizes from R25 to R51.

T-type is according to international standard, and is available in sizes from T30 to T103.

FRP bolts are made out of fiberglass and are available from S15 to SXX in both solid and hollow versions.

Henan Zongxiang Heavy Industry Import & Export Co., Ltd, established by experienced crew on the rail & track field, is a professional & reliable supplier that provides all kinds of rail & track accessories.

As an international trade subsidiary of Zhongxiang Steel Group Inc., was founded in 1997. We have more than two decades experience on this field, covering an area of 33,000 square meters, with about 300 employees, 4 production lines, 2 R & D department, and 5 quality control staff. With advanced technology, powerful processing capacity and excellent service, our products have been well recognized by our customers from domestic & overseas market.

Our products mainly used by railroads, mining companies, heavy industries, overhead crane, railroad and tunneling industry, transit authorities, and operators of port facilities.We have the inventory, resources, and experience to meet your needs.