In recent years, with the development of mining enterprises, the types of mining support products in China have been increasing. As a strong support manufacturer, Zongxiang Steel Group has developed like a bamboo shoot in the past few years and has made rapid progress. Today Zongxiang introduced the screw-thread steel anchors for everyone to make them known.

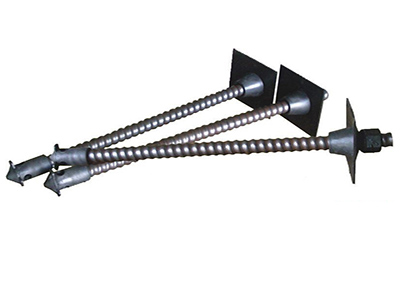

Screw-thread steel anchor is a new type of rock bolt that saves material, saves labor, and has the same strength. It has a broad application prospect and is currently recognized by many markets. Its structural feature is that the full length of the rod body has rolled continuous threads, the full length is of equal strength, and the fastening end is provided with a prestressed washer and a ball head nut. It can also expand the range of use of anchor rods, and can realize solutions such as end anchors, extended anchors and full anchors.

There are two types of left-handed and right-handed bolts for screw-thread steel anchors used in mining. The nuts are special and the specifications are 16mm, 18mm, 20mm mm. This kind of anchor rod made by special processing technology has high-quality features such as high strength, reasonable structure, and large pre-tightening force. It can also automatically adjust the direction of the force, increase the restraining force on the surrounding rock, and realize rapid mechanical installation. The strength of the thread segment is greater than the strength of the rod body, and the bending and shear resistance is good. End anchors, extension anchors and full anchors are mainly used for high-strength support of high-deformation roadways in high ground pressure mines, and also for high-strength and long-lasting roadway support of railways, hydropower and other projects.

Use of screw-thread steel anchors:

1. Determine the anchor hole position according to the design requirements, and drill with a drill;

2. Use compressed air to blow out the rock dust in the hole;

3. Send the anchoring agent to the bottom of the hole, and use the anchor rod to start the stirring. After the stirring is complete, remove the stirring machine. After the waiting time is reached, remove the stirring connector, install the anchor disk, ball washer, and friction washer. Special wrench tightens the nut.

Email: zxminesupport@zxsteelgroup.com

Whatsapp: +86 18236766038

PREVIOUS POST

Notes On Using The Anchor PlateGet the Price

Online Chat

To top